Visualization / IoT

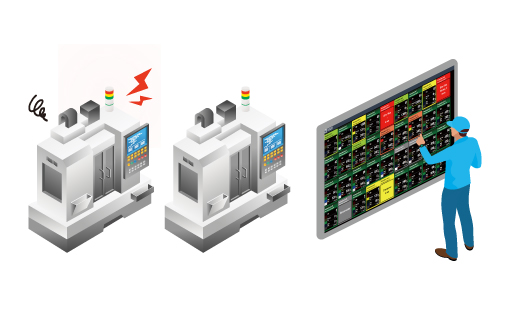

IoT (Internet of Things) in manufacturing involves connecting equipment and devices on the production floor to a network, enabling real-time data collection, management, and analysis. This technology aims to enhance production efficiency and optimize maintenance operations. By utilizing IoT devices installed within factories, various data points such as operating time, downtime, abnormal signals, vibration frequency, temperature, humidity, and energy consumption are visualized. This allows for a centralized understanding of production progress and equipment status, facilitating preventive maintenance and improvements in production efficiency.

Benefits

- Real-Time Monitoring and Visualization of Equipment Operating Status

By utilizing IoT devices, data on equipment operating time, downtime, and abnormal signals is visualized in real-time. This enables continuous awareness of the production status on-site, allowing for the optimization of operational efficiency. - Efficiency of Maintenance and Predictive Maintenance

By analyzing data on vibration, temperature, humidity, and energy consumption, early signs of abnormalities can be detected, facilitating predictive maintenance. This helps prevent unexpected machine failures and downtime, ultimately reducing maintenance costs. - Efficient Energy Management

Through monitoring the energy consumption of equipment, it is possible to understand energy usage patterns and minimize unnecessary energy expenditure. This enhances the overall energy efficiency of the factory and contributes to cost savings. - Improvement of Production Quality

Analyzing data provided by IoT devices clarifies areas for improvement in the production process, aiding in enhancing product quality. It enables effective management of factors influencing product quality, such as temperature, humidity, and cutting fluid. - Streamlining Operations and Optimizing Processes

By integrating and managing data from each piece of equipment, operational processes can be streamlined, achieving optimal functioning of production lines. This enables rapid decision-making based on data, resulting in increased overall productivity.