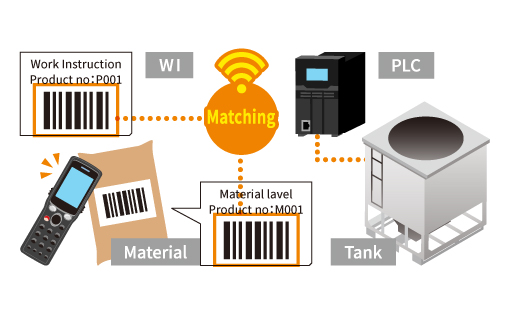

Unlocking System

The Unlocking System is designed to mitigate the risks of material picking errors and incorrect material input in the manufacturing industry. When materials are fed into the molding machine, the tank is locked, and the lock can only be released after verifying the material data through a comparison process. The lock is released only when the correct material is selected; if the wrong material is chosen, the lock remains engaged, thus providing a physical barrier against incorrect material input. Control is managed by a PLC, ensuring high-precision material management.

Benefits

- Prevention of Picking Errors

The system automatically verifies whether the materials are correctly selected. If there is a mismatch, the lock remains engaged, thereby preventing picking errors and incorrect material input before they occur. - Reduction of Production Loss

By physically preventing the input of incorrect materials, the system reduces waste and the need for re-production, leading to a decrease in overall production loss. - Enhanced Quality Control

Ensuring the correct materials are reliably input stabilizes product quality, thereby strengthening quality management throughout the manufacturing process. - Simplified Operation

The locking and unlocking functions are automated, allowing for accurate material input without relying on the judgment of on-site personnel. This reduces operational hassle and improves efficiency. - Improved Safety

The system is designed to prevent the input of incorrect materials, enhancing safety in the manufacturing process and preventing accidents or issues caused by the use of incorrect materials.