Utilizing IoT (Internet of Things) is gaining attention in Thailand’s manufacturing industry. However, many may feel uncertain, thinking, “I don’t know what can be done,” “I’m unsure where to start,” or “I’ve been instructed from above, but it’s hard to explain.”

This article explains specific examples and key points of using IoT for on-site improvements in Thai factories. It aims to dispel the image of IoT being “difficult” or “expensive” and introduces ways to start utilizing IoT on a small scale.

Reasons for the Progress of IoT Implementation in Thailand

In recent years, the adoption of IoT in Thailand’s manufacturing industry has accelerated. Factors such as the government’s industrial advancement policy “Thailand 4.0,” expectations for maintaining competitiveness through productivity improvements, and the declining cost of sensors have made IoT accessible not only to large corporations but also to small and medium-sized enterprises. As a result, the use of IoT is becoming more common in Thailand’s manufacturing sector.

Challenges in Manufacturing Sites That IoT Can Solve

How can IoT specifically help solve on-site challenges? Let’s look at common issues in manufacturing sites and how IoT can address them.

Machine stoppage or abnormality is “too late to notice”.

When relying on human observation, abnormalities in production line machinery may be detected too late, leading to breakdowns. IoT is effective for detecting such machine anomalies.

By continuously monitoring temperature and vibration with sensors and notifying of abnormal values, early signs of failure can be detected. Planned maintenance can prevent sudden line stoppages, reducing production losses and repair costs.

Ambiguous or Delayed Recording of Work Results

Manual recording in manufacturing sites often leads to errors or omissions. For example, recording operating time or production quantity by hand may result in oversights or mistake.

Using IoT allows for automatic collection and recording of such data, accumulating accurate and consistent information. Real-time understanding of situations becomes possible, and reliable data can be utilized for subsequent analysis. Improving the accuracy of records previously reliant on paper or Excel is a significant advantage of IoT.

Fragmented Data Across Equipment

In factories, data is often fragmented across departments, making it difficult to grasp the overall picture or conduct cross-sectional analysis. By aggregating information from each piece of equipment into a single platform using IoT, factory visualization can be achieved.

Production numbers, operating rates, quality, equipment status, and other data can be viewed centrally, enabling correlation analysis. Establishing a data infrastructure through IoT leads to swift and accurate decision-making.

Recommendations for IoT Implementation in Thai Factories

If you’re wondering, “I understand IoT can solve issues, but where should I start?” here are some examples of IoT applications suitable for small-scale implementation in Thai factories. These examples require relatively low costs and short periods for implementation without large-scale system investments.

Quality Control Using Temperature and Humidity Sensors

Temperature and humidity control within factories affect product quality and equipment lifespan. Given Thailand’s hot and humid climate, IoT systems that continuously monitor the environment with sensors and alert upon detecting abnormal values are effective.

For instance, installing temperature and humidity sensors in parts storage areas can detect temperature rises or condensation, prompting countermeasures. This helps prevent quality issues in advance. Temperature and humidity sensors are relatively inexpensive and can be easily introduced with a wireless network.

Monitoring Production Line Operations

Traditionally, it has been challenging to accurately determine when and how much each machine operates. By attaching IoT sensors, operating times and stop counts of each device can be automatically recorded.

For example, sensors detecting current or vibration can capture on/off states, allowing calculation of operating rates for each line. Operational monitoring can be retrofitted to existing equipment and serves as an effective first step in improvement activities by identifying inefficiencies through data.

Automatic Counting of Component Quantities and Inventory

Monitoring the remaining quantities of consumables like screws or parts using IoT is another application. Instead of manual inventory checks, sensors attached to containers or supply devices can automatically detect remaining quantities.

For example, sensors measuring container weight can estimate the number of items inside, and when the quantity falls below a certain level, lights or notifications alert the responsible personnel. This prevents line stoppages due to stockouts and enables timely replenishment orders. Such solutions can address on-site issues without large-scale systems.

If you’re interested in trying out IoT applications like these in your factory, please feel free to consult with us.

Three Key Points for Successful IoT Implementation

Starting with small examples is possible for IoT implementation, but it’s essential to keep certain points in mind for success. Here are three crucial points to ensure the success of IoT projects in Thai factories.

“Start Small” Without Expanding to All Processes Immediately

Starting small is the key to successful IoT implementation. Instead of attempting to IoT-enable the entire factory at once, begin with a single line or machine.

By testing within a limited scope, you can verify effectiveness while minimizing costs and risks. Accumulating small successes makes it easier to gain internal support and gradually expand the scale.

Not only at “Visualization”

Achieving data visualization through IoT is not the end goal. The collected data should be linked to on-site decision-making and improvement actions to realize its value.

For example, instead of being satisfied with visualizing operating rates, discuss “why is it low?” on-site and implement countermeasures. Utilize data as a tool for on-site improvements, leading to equipment adjustments and work procedure reviews.

Design with Post-Implementation Operation and Maintenance in Mind

IoT implementation isn’t complete upon introduction; planning for ongoing operation and maintenance is necessary. If enthusiasm fades after initial implementation and no one monitors the data, the system becomes ineffective.

To prevent this, clarify operational workflows from the start, such as “who checks the data and how to respond to abnormalities” and “who maintains the sensors.” Assign responsibilities and incorporate data checks into daily operations to ensure the IoT system becomes established on-site.

Also, account for maintenance tasks like sensor calibration, battery replacement, and software updates in advance. Educating local staff is crucial. Provide explanations, prepare manuals, and establish a support system to enable long-term, reliable use of IoT.

TOMAS TECH’s IoT Implementation Support

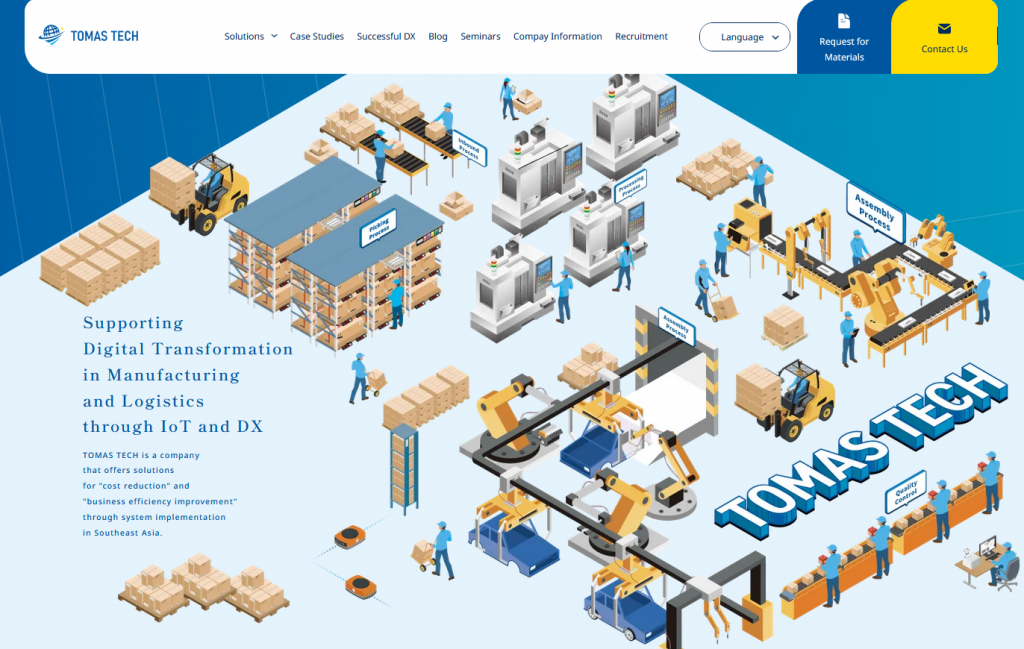

TOMAS TECH offers comprehensive support for IoT implementation in Thailand’s manufacturing sites, from on-site surveys to sensor design and operational support. If you’re hesitant to proceed alone or seek a reliable local partner, please consider our services.

Our staff conducts on-site surveys to propose IoT solutions tailored to your challenges. We select optimal sensor devices and communication methods to build the system. Post-implementation, we provide support until the system is established on-site, including operational training for local staff and support in local languages. For more details on our services and achievements, feel free to contact us.

Frequently Asked Questions About IoT in Thailand

Here we answer frequently asked questions about IoT implementation in Thailand.

A: With the declining costs of sensors and communication devices, along with affordable cloud services, small-scale systems can be started from several tens of thousands of THB. If cost is a concern, we recommend starting small to assess effectiveness.

A: By building a local network within the factory and storing data on an in-house server, operations can continue even with unstable internet connections.

A: As long as the system is designed from the on-site perspective—for example, with a simple and intuitive interface—there should be no problem. Also, providing thorough explanations and training during implementation, and clearly communicating how IoT will make daily tasks easier, can reduce resistance. Help staff understand the benefits, such as “less time spent on handwritten records” or “immediate alerts for abnormalities.”

Conclusion: IoT is not just for “equipment visualization” —it’s a tool for “supporting on-site decision-making”

IoT is not merely a cutting-edge technology; it’s a practical tool for solving real challenges on the factory floor. Don’t be discouraged by the impression that it’s “too complicated” or “too expensive.” Start small with a familiar, manageable theme. The true value of IoT lies not in visualization alone, but in using that data to drive decisions and improvements on-site.

If you’re unsure about how to apply IoT within your company, consider using expert support services.

Please don’t hesitate to contact TOMAS TECH using the button below.