At factories in Thailand, issues such as the limitations of paper-based operations, task dependency on individuals, and fragmented information significantly hinder daily work efficiency. Many companies struggle with the question: “We want to promote DX on the shop floor, but we don’t know where to start.”

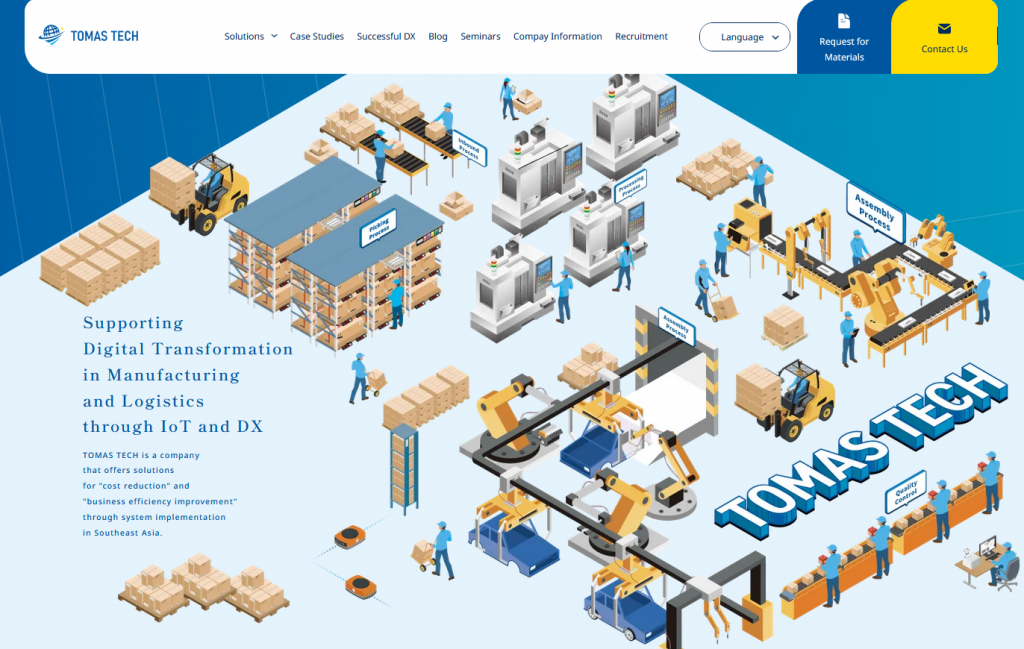

This article explains, from an on-the-ground perspective, how to promote DX step-by-step in Thai factories, how to set priorities, implementation steps for success, and the support provided by TOMAS TECH.

Background of DX Challenges in Thai Factories

Let’s begin by understanding the background of DX challenges in Thai factories.

The drawbacks of paper-based operations that burden the shop floor

Reliance on paper checklists and handwritten records leads to input errors and delays in information sharing, which in turn causes a drop in productivity.

Risks caused by task dependency and difficulties in knowledge transfer

When know-how is held only by specific individuals, operations become unsustainable during personnel changes or retirements, posing risks such as quality decline or production halts.

Decision-making delays due to disconnected information across and beyond the factory

When production data is not shared between departments or with the Japanese headquarters, it causes issues like inventory mismanagement and report delays, impacting the speed of business decisions.

DX Promotion Strategy and Prioritization: Start Small and Achieve Steady Results

Let’s now explore the DX promotion strategy and prioritization.

DX is not achieved in one leap—it must be approached in stages

Rather than attempting full factory automation from the start, it’s important to build up improvements through small changes on-site. DX is a long-distance run—gradual transformation helps embed change at the ground level.

Set priorities and plan actions based on on-site challenges

Don’t try to solve every issue at once. Start with problems that have the widest impact, such as eliminating paper-based management or sharing quality data. Listen to on-site voices, assign priorities, and drive DX in a planned manner.

Digital technology is a means, not the goal—focus on process improvement

When introducing DX, the objective often shifts to adopting the latest technology itself. However, the essence of DX lies in improving business processes. Make sure the purpose of DX is clear so that the on-site team understands and participates in creating value through human-digital collaboration.

Implementation Steps: 3 Stages to Successful DX in Thai Factories

Let’s walk through the three stages of successful DX in Thai factories.

Step 1: Identify inefficiencies and begin with visualization

Choose one point of improvement on the shop floor and start by visualizing operations managed on paper or Excel. For example, use sensors or simple systems to collect data on equipment utilization or defective product counts and gain a clear view of current operations.

Step 2: Start small by digitalizing a high-priority issue

From the data gathered in Step 1, select the most critical issue and test a targeted digital solution. Small initiatives—such as issuing work instructions via tablets or sharing daily reports on the cloud—allow you to assess the effectiveness and challenges of digital tools.

Step 3: Scale successful initiatives and connect systems for optimization

Improvements that worked in one area should be expanded to other lines or processes. Connect the individual systems introduced earlier, and move toward centralized data management across the entire production site. This leads to overall factory optimization and improved efficiency.

TOMAS TECH’s Support: On-the-Ground Assistance for Step-by-Step DX

TOMAS TECH provides the following support:

- IoT Implementation Support: Attach add-on sensors to factory equipment to collect operational data, enabling visualization and anomaly detection. Begin digitalization cost-effectively using existing equipment.

- Process Management System Development: Build systems to digitally manage progress and procedures on the production line. This enables real-time visibility into on-site operations, reducing delays and errors.

- Inventory and Core System Integration: Connect data from the shop floor with inventory management systems and the headquarters’ ERP. This prevents stockouts and overstock, achieving seamless integration between operations and management.

- IT Training for On-Site Staff: Provide bilingual training (Japanese and Thai) and prepare manuals to ensure that local staff can effectively use new systems. We stay involved until DX becomes ingrained in your operations.

If you’re aiming to drive DX in your Thai factory, don’t hesitate to reach out via the button below.

Case Study: A Success Story of DX Implementation in a Thai Factory

Achieved 80% Downtime Reduction and Doubled Production through IoT

A Japanese manufacturer operating a factory in Thailand faced challenges with unexpected equipment breakdowns due to aging infrastructure. With TOMAS TECH’s support, IoT sensors were installed to monitor equipment status, enabling predictive maintenance through early anomaly detection.

As a result, downtime was reduced by 80%, and production volume nearly doubled—a prime example of how small steps can lead to significant outcomes.

Frequently Asked Questions About Promoting DX in Thai Factories

This section provides answers to frequently asked questions about DX promotion at Thai factories.

Q: Isn’t DX promotion extremely expensive?

A: Not necessarily. You can start with low-cost initiatives, such as adding affordable IoT sensors to existing equipment. Using cloud services eliminates the need to purchase servers, and you can access essential features while keeping initial costs low. The key is to assess cost-effectiveness and invest incrementally. By building on small successes, you can secure future budgets without overextending.

Q: I don’t know where to begin…

A: Start by identifying issues on the ground and pick one with high potential impact. For example, “Daily reports are on paper and take too long to compile.” Begin with such manageable problems. Try out small improvements and expand based on results—this makes DX more acceptable to the team.

Q: I’m worried if Thai staff can handle IT tools.

A: Education and support are critical for adoption. At TOMAS TECH, we offer training in both Japanese and Thai, along with quick support for staff whenever needed. By choosing user-friendly cloud systems, even staff unfamiliar with IT can gradually adapt. Our hands-on support ensures peace of mind.

Q: Is DX the same as factory automation?

A: They are different. Automation is just one part of DX. DX is about transforming how work is done using digital technology—it’s a broader initiative aimed at creating new value by combining human capabilities with digital tools. It includes reviewing workflows, improving information sharing, and making work easier for people—not just installing robots.

Conclusion: Small On-Site Improvements Are the Key to Successful DX

In this article, we examined how to drive DX in Thai factories by starting from real on-site issues and following a step-by-step improvement approach. There is no need to change everything at once. By starting with small, tangible improvements based on on-site challenges and steadily accumulating success, you can achieve remarkable transformation over time.

Taking a calm, consistent approach is the fastest path to DX success. TOMAS TECH is fully committed to supporting DX from the ground up. Please feel free to contact us.