Expanding a factory into Thailand requires building an operational structure from scratch in a different cultural and environmental context than Japan. A commonly overlooked but critical risk is insufficient preparation of the information infrastructure.

In particular, if production control and business workflows are not properly established before operations begin, it can lead to confusion, rework, and a chain reaction of troubles.

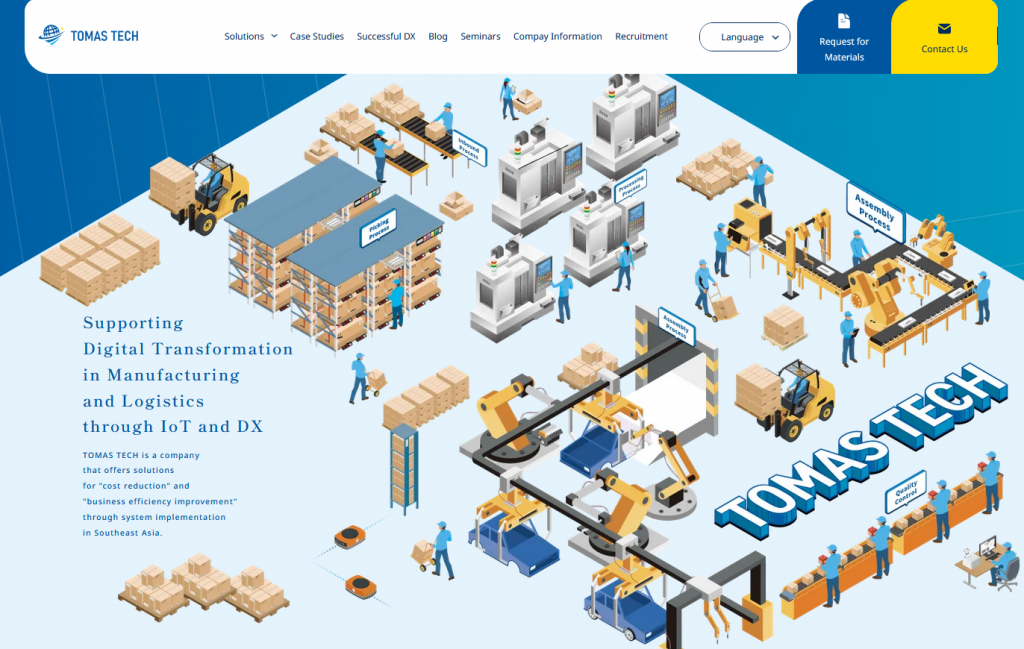

In this article, we explain in detail the common mistakes made during factory launches in Thailand and how to avoid them, as well as the importance of designing operations from a DX (Digital Transformation) perspective from the early stages—based on the extensive local experience of TOMAS TECH.

Common Mistakes When Expanding Factories into Thailand

Let’s explore the typical pitfalls companies face when setting up factories in Thailand.

Launching operations without proper systems leads to confusion on the shop floor

When companies focus solely on preparing equipment and hiring personnel, leaving production control systems and workflow development behind, operations end up relying on paper and Excel as stopgap measures. This leads to delays in grasping inventory and production status, resulting in frequent mistakes and issues.

Delaying business standardization leads to costly rework

If standardizing and documenting business processes is neglected at launch, each department starts operating based on individual practices. Later attempts to unify systems and rules face heavy resistance, resulting in unnecessary training costs and downtime—dampening the momentum of the initial rollout.

Lack of communication between HQ and local site complicates management

If the Japanese HQ and the Thai factory are not integrated through a unified business system, information sharing on inventory and orders is delayed. Daily reports must be handled manually, burdening HQ’s administrative team and making it difficult for overseas operations to get off the ground smoothly.

Prioritizing for Success: Build a Foundation from a DX Perspective Early On

Create standardized business processes during preparation, not after launch

Rather than scrambling to build structure after operations begin, it is vital to establish a “template” for business workflows during the preparation phase. By defining standard processes—such as how to create production plans and conduct quality checks—and sharing them with all staff, confusion at the start of operations can be avoided.

Plan for scalable core systems from the beginning

Even if production starts small, select a system infrastructure with future expansion in mind. For example, choosing cloud-based systems for production and inventory management allows for easy function upgrades and multi-site integration later on. It’s important to plan for a structure that supports growth while keeping initial investments low.

Prioritize core business functions like production and quality

With limited time and resources, prioritization is essential. In manufacturing, establishing systems for production planning, performance tracking, and quality control should come first. A stable foundation here enables smoother digitalization of surrounding processes later.

Implementation Roadmap: 4 Steps to Establish Operations in a New Thai Factory

Here are the four key steps to structuring operations in a new factory in Thailand.

Step 1: Define operational requirements during the planning phase

At the outset of the Thailand expansion project, define business requirements based on production volume, product characteristics, and local staffing. Identify which systems and rules are needed at each stage of production, referencing HQ standards to draw up the ideal business flow.

Step 2: Install and configure essential systems before operations begin

When physical setup of the factory is complete, implement core systems such as production and inventory management. Register master data and configure access rights so the systems are ready to use from Day 1. If necessary, run equipment–system connection tests to ensure seamless data integration.

Step 3: Train staff and verify workflows through dry runs

After implementation, conduct system operation training for local staff before operations begin. Use actual production lines to perform trial runs and check whether operations align with defined workflows. Identify and correct issues, incorporating feedback from the floor to refine the system for real-world use.

Step 4: Optimize operations post-launch and expand DX in stages

Once operations commence, regularly monitor usage and identify areas for improvement. Add features or integrate with other systems as needed to improve efficiency. Once production stabilizes, gradually introduce new DX initiatives such as IoT-based equipment monitoring or predictive maintenance, helping enhance competitiveness.

TOMAS TECH’s Support: End-to-End Partnership from the Start

Here’s how TOMAS TECH supports clients during their factory expansion into Thailand:

- Operational Design Consulting:

Participate from the planning phase before launch to help design workflows tailored to local conditions. We propose optimal processes based on HQ standards. - System Implementation Support:

Help select and implement necessary IT systems—like production and inventory management—on-site. We handle everything from hardware setup to configuration and testing, ensuring a ready-to-use environment by launch. - Staff Training & Operational Adoption Support:

Provide training in Japanese and Thai to local staff and follow up until the system becomes fully adopted on-site. We also assist with manual preparation and support inquiries during early operations. - Post-launch Improvement Proposals:

After launch, conduct regular visits to identify operational challenges. Propose the next phase of DX, such as IoT integration or additional system development, and support ongoing improvements together with your team.

If you want to avoid failure during your factory expansion into Thailand, click the button below to get in touch with us.

Case Study: A Smooth Launch Through Early DX Adoption

Here’s a success story of a company that adopted DX from the beginning.

Case: Japanese Manufacturer A — Achieved stable operations in a short time by implementing standard systems from launch

Japanese Manufacturer A partnered with TOMAS TECH from the construction stage of their new factory in Thailand. They implemented production and quality control systems early on and built a data-driven management structure from Day 1. As a result, production stabilized according to plan immediately after launch, and defect rates were reduced by 50% early on.

The system also allowed them to respond quickly to increased production needs, getting the Thai factory up and running at full capacity in a short time. Early DX adoption was a key factor in this successful launch.

Frequently Asked Questions about Factory Launch and DX in Thailand

From here, we will answer some frequently asked questions about factory expansion and DX (Digital Transformation) in Thailand.

Q: We don’t have the budget to invest in systems from the beginning. What should we do?

A: Even with a limited budget, starting small in high-priority areas can still deliver strong results. For example, start by digitalizing inventory management, while keeping other tasks manual. Building a foundation early enables gradual expansion—and avoids higher costs from future troubleshooting. Cloud services can also help minimize upfront costs.

Q: Which operations should we digitalize first when launching a factory?

A: Start with core operations such as production planning, performance management, and inventory management. These have the greatest impact on overall factory efficiency. Non-core tasks can be handled manually at first. Focus DX efforts where they will have the biggest impact, tailored to your factory’s size and industry.

Q: Can we operate the system even without on-site IT staff?

A: Yes. Cloud-based systems require minimal local maintenance, and local IT partners like TOMAS TECH can manage system operation and maintenance. On-site staff can handle daily tasks with proper training, and remote monitoring by HQ can also be arranged if needed.

Q: Is DX beneficial even for small factories?

A: Absolutely. In fact, small factories with limited staff often benefit more from DX. Reducing paper-based work and automating calculations can significantly increase productivity. Fewer staff also makes it easier to introduce and adopt new tools. With minimal investment, even small factories can achieve high efficiency and strong competitiveness.

Conclusion: Laying a DX Foundation Early Accelerates Future Growth

To succeed in expanding a factory into Thailand, early-stage process design and DX planning are essential. Rather than retrofitting systems later, establishing a foundation from the beginning avoids confusion and enables both a faster launch and future scalability. TOMAS TECH provides comprehensive local support from the preparation phase—including process standardization, system implementation, and operational support.