Many managers and IT personnel at Japanese companies with manufacturing bases in Thailand may be instructed by their headquarters to “promote DX (Digital Transformation)” but are unsure where to start.

DX refers to initiatives that transform business processes and models using digital technologies.

However, DX does not equate to full automation of factories; the key to success lies in accumulating small improvements and embedding them in the workplace.

This article gently explains the background of promoting DX in Thailand’s manufacturing industry, on-site challenges, specific steps to proceed gradually, implementation examples, and frequently asked questions. It addresses the concerns of those hesitant to take the first step in DX and introduces solutions.

Background of the Demand for DX in Thailand’s Manufacturing Industry

Why is DX now required in Thailand’s manufacturing industry? The background includes changes in the business and labor environments. Thailand is one of ASEAN’s leading industrial countries, with a concentration of diverse manufacturing industries such as food, petrochemicals, and electronic components, and many Japanese companies have entered the market.

In recent years, competition has intensified due to changing market needs and the rise of Chinese companies, increasing the need to review traditional methods. Additionally, the Thai government launched a national vision called “Thailand 4.0” in 2015, promoting the development of next-generation industries and the advancement of manufacturing.

In response, manufacturing companies are required to engage in DX initiatives utilizing digital technologies for labor-saving, efficiency, and quality improvement. Furthermore, Thailand is expected to face a decline in the working-age population due to a decreasing birthrate, making it urgent to address future labor shortages.

There is also increasing pressure from Japanese headquarters to improve productivity and standardize operations at overseas factories, making DX indispensable. Thus, both market/policy and labor aspects are driving the push for DX in Thailand’s manufacturing sites.

Sources:

デジタル化や脱炭素に、日系企業は(タイ) | 地域・分析レポート – 海外ビジネス情報 – ジェトロ

Common On-Site Challenges in Thailand’s Manufacturing Industry and the Necessity of DX

Next, let’s look at common challenges in Thailand’s manufacturing sites and why DX is necessary to address them. Please consider whether these issues are present in your workplace as you read.

Management Using Paper, Verbal Communication, and Whiteboards

Inability to grasp production status in real-time leads to delays in problem detection and response—a challenge seen in many factories. Using paper check sheets and manual aggregation causes time lags in information and increases the likelihood of errors.

Without visualizing on-site data, it’s impossible to quickly identify and improve waste and bottlenecks. Establishing a foundation to collect and visualize on-site data through DX is essential to start improving efficiency.

Dependence on Individualized Management

In Thailand, frequent job-hopping leads to structural issues where know-how is lost whenever employees or expatriates change.

Relying on individualized methods makes it difficult to maintain quality and productivity. However, by standardizing and sharing work procedures and know-how digitally through DX, it’s possible to maintain on-site capabilities even when personnel change. Creating systems that don’t depend on individuals is essential, making DX indispensable.

Sources:

DXを通じた業務標準化に貢献(タイ) | 地域・分析レポート – 海外ビジネス情報 – ジェトロ

Lack of Consolidated On-Site Information Hindering Improvements

Inefficient information sharing within and outside the factory is another significant issue. For instance, even after production is completed, updating inventory data and reporting to headquarters may take time, and machine failure information may not be promptly shared with relevant departments.

This occurs because systems for production management, inventory management, and maintenance management are fragmented and lack data integration. By connecting process data within the factory to inventory and sales systems through DX, it’s possible to eliminate communication delays, prevent stockouts and overproduction, and improve overall efficiency.

If you’re facing challenges on-site, consider taking the first step toward solutions through DX. Please consult with a TOMAS TECH representative.

Three Steps to Successfully Implement DX in Thailand

So, what specific procedures should be followed to promote DX on-site? For those unsure where to start, here are three practical steps to implement DX in Thailand’s manufacturing sites.

There’s no need to aim for advanced solutions from the beginning. Proceed step by step.

Step 1: Identify On-Site “Inefficiencies”

The first step is to start visualizing the site. Begin by selecting one issue you want to improve within the factory and introduce a small-scale data collection mechanism related to it.

For example, attach IoT sensors to some equipment to measure operating time or switch from paper daily reports to tablet input. There’s no need to change the entire factory at once. By trying digitalization in a limited area, you can objectively identify the causes of problems previously based on intuition and experience.

Step 2: Start Small with Digitalization

The next step is to implement improvement measures for the issues identified from the data. Analyze the data collected in Step 1, select one high-priority issue, and try solving it on-site using digital technologies.

For instance, if machine failures are frequent, introduce preventive maintenance; if progress is unclear, try a work management system. The key here is to create small successes.

If introducing IoT monitoring on one line reduces waiting time, share that success story across the site to foster an atmosphere of “this is convenient” and “let’s try it elsewhere.” When on-site personnel experience the benefits of DX, resistance decreases, and cooperation becomes easier.

Step 3: Strengthen System Integration and Visualization

The final step is to expand the achieved effects and aim for overall optimization. If a method worked well in Step 2, extend it to other equipment or lines. Also, integrate individually introduced systems to manage data centrally across the factory.

For example, link production data with inventory systems to automatically update inventory information or connect with headquarters’ core systems for global standardization. By connecting scattered improvements, establish a system where information flows seamlessly within and outside the factory, maximizing the benefits of DX.

Case Study: Successful DX Implementation in Thailand’s Manufacturing Industry

Some may worry, “Even if we proceed step by step, will we really see results?” Here’s a case where a Japanese manufacturer’s factory in Thailand introduced IoT, resulting in an 80% reduction in downtime and approximately doubling production volume.

This demonstrates that engaging in DX can yield significant quantitative effects. Of course, not all cases will achieve the same results, but accumulating small improvements can lead to remarkable productivity gains over the years. Please consider starting DX where possible in your company.

Frequently Asked Questions About DX in Thailand’s Manufacturing Industry

Here are answers to common questions about DX in Thailand’s manufacturing industry.

A: No, DX does not necessarily mean full automation. While using robots and AI is part of DX, it’s not the sole goal. The essence of DX is to improve work processes using digital technologies, combining people and technology to create value. Automation is just one means; the primary objective is on-site improvement.

A: Significant investment isn’t always required. Starting small, such as adding inexpensive IoT sensors to existing equipment to collect operational data, can suffice. Utilizing cloud services eliminates the need for in-house servers, allowing you to use necessary systems with minimal initial costs. The key is to evaluate cost-effectiveness and invest gradually. By securing the next budget based on the results of small successes, you can advance DX efficiently.

DX Support for the Thai Manufacturing Industry by TOMAS TECH

“If we try to promote DX on our own, we feel uncertain. We want a reliable partner to support us.”

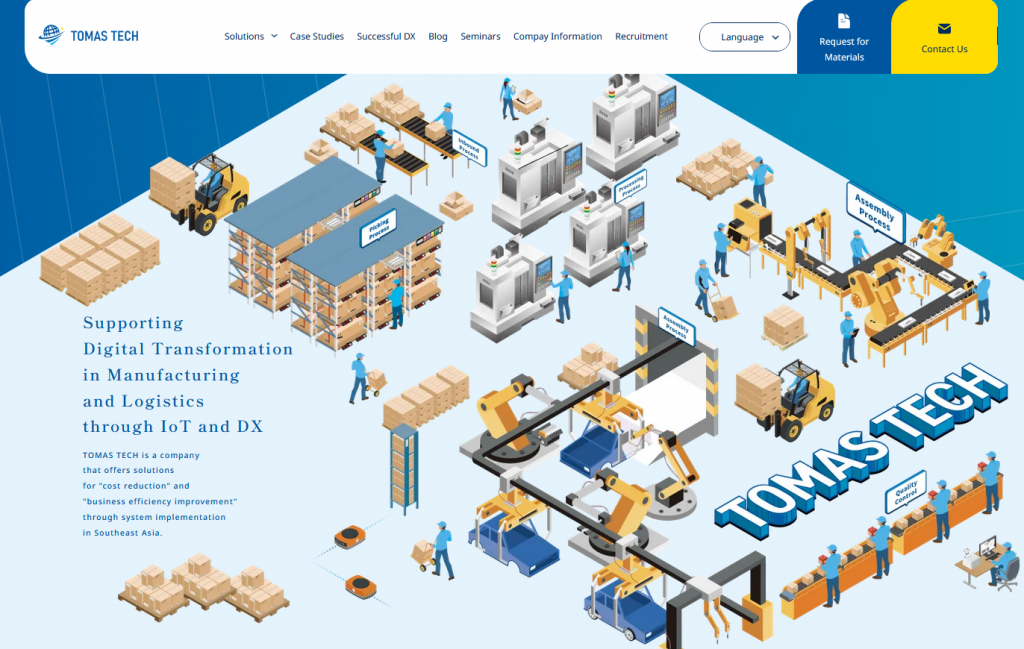

If you feel this way, consider leveraging the DX support services provided by TOMAS TECH, specifically designed for companies expanding into Thailand.

TOMAS TECH offers one-stop DX support specialized for the Thai manufacturing industry, walking alongside clients from the very first step — even if they are unsure where to begin.

We propose phased plans tailored to each factory and aim to achieve significant results by building up small successes.

Here are our main services:

- IoT Implementation Support:

We install sensors on factory equipment to collect operational data, enabling visualization and anomaly detection. - Digitization of Process Management:

We build systems to manage production line progress and work procedures, allowing real-time monitoring of on-site conditions. - Integration with Inventory and Core Systems:

We link production data from the factory with inventory management systems and ERP (core systems).

Synchronizing production and inventory information helps prevent stock-outs and overstocking.

In addition, we offer comprehensive support until DX takes root in the workplace, including IT training for local staff and bilingual support in Japanese and Thai.

With TOMAS TECH as your partner, you can move forward with DX with peace of mind.

Please feel free to contact us to get started.

Summary: “Step-by-step improvement” is the key to successful DX in Thai manufacturing

In this article, we have explored the promotion of DX in the Thai manufacturing industry, from background context to specific strategies.

What’s important is not to treat DX as something special, but to steadily accumulate small improvements on the shop floor.

There’s no need to change everything all at once. Taking your time and progressing steadily is the shortcut to success. Start today with what you can do now.

Believe that a small step today can lead to a great leap in the years to come — and take on the challenge of DX with confidence.