Japanese manufacturing companies with production bases in Thailand often face various challenges in on-site management.

For instance:

- “Delays in the field are hard to improve”

- “Forms are still on paper, leading to inefficiencies”

- “Training for Thai staff is person-dependent and lacks standardization”

If any of these concerns resonate with you, this article aims to identify common issues in production management in Thailand and provide realistic improvement steps.

Additionally, we introduce successful improvement cases in Thailand and the support provided by TOMAS TECH for Japanese companies.

Common Challenges in Production Management in Thailand

In Thailand, where factory operations are conducted in a culture and customs different from those in Japan, there are common production management challenges. Here we will look at three issues that are common at local manufacturing sites in Thailand.

Production Does Not Proceed as Planned

In Thai production sites, delays in the production schedule often occur without thorough investigation or recurrence prevention, leading to repeated delays. For example, delays in parts delivery or line stoppages may rely on paper reports or verbal communication, making it time-consuming to grasp the situation and resulting in delayed countermeasures.

Furthermore, when Japanese expatriates manage multiple sites remotely, it becomes difficult to grasp progress in real-time, hindering delay improvements.

Visualizing the situation to identify delays and their causes is necessary, but person-dependent management and paper-based information make it challenging to grasp the overall picture and formulate effective improvement measures.

Inability to Grasp Inventory and Progress in Real-Time

Many Thai factories still operate with paper-based forms (daily reports, inspection records, inventory sheets), leading to time-consuming entries and circulation, and causing time lags in information sharing.

For example, production quantities and defect information recorded on paper are later re-entered into Excel by staff, resulting in redundant work and potential human errors, affecting data accuracy and usability.

Additionally, searching past information on paper documents takes time, slowing down the overall pace of the site.

Person-Dependent Management and Untransferable Training

Training of local staff in production management often relies on individual experience and intuition, lacking standardized manuals and systems.

For instance, Japanese supervisors or veteran Thai staff may conduct one-on-one on-the-job training, leading to varying proficiency levels among new employees depending on the trainer.

Such person-dependent training means that when a trainer is transferred or leaves, the know-how is lost. In Thailand, job-hopping is common, and trained personnel may leave, posing a challenge.

Relying on verbal handovers without organized training materials prevents the establishment of a “non-person-dependent system,” leading to unstable management levels and a vicious cycle.

These challenges are common among many Japanese companies. Recognizing your company’s issues is the first step toward improvement. If any of these points apply to you, consulting with experts for an objective analysis may be beneficial. Why not consult with professionals in problem-solving?

Three Steps to Improve Production Management in Thailand

To address the aforementioned challenges and improve production management in Thailand, a phased and planned approach is essential. Here we introduce three steps to effectively promote improvements locally.

Visualize On-Site Issues

The first step is to organize local requirements. Identify the unique circumstances and constraints of Thai factories and uncover the true needs of the site. Rather than imposing ideals from the Japanese headquarters, conduct interviews with local managers and workers to visualize the problems.

Bridging the gap between Japanese and Thai staff may require interpreters or local consultants to accurately capture on-site voices. Once current issues are clarified, it becomes easier to determine the next steps for improvement.

Start with Simple IT Tools

Next, implement solutions gradually. Attempting a large-scale overhaul all at once can cause confusion and resistance on-site. Starting small and progressing steadily is key. For example, begin by switching from paper forms to tablet input. Even just digitizing daily reports can speed up information sharing and yield noticeable effects.

As data accumulates, expand DX (Digital Transformation) to production planning and inventory management. A phased approach allows staff to acclimate to new systems, and any issues can be managed with minimal impact. Taking it step by step is the shortcut to success.

Aim for System Integration for Overall Optimization

Finally, strengthen information linkage between processes to achieve overall optimization. Production management involves multiple departments such as procurement, manufacturing, logistics, and quality. Partial improvements have limitations. Integrate data across processes to enable real-time information sharing beyond departmental boundaries. For example, link production schedules with parts inventory, and integrate systems so that progress and issues can be shared instantly between processes.

This prevents communication breakdowns between processes, allowing the entire factory to collaborate and enhance productivity. Management can also grasp the overall situation through integrated dashboards, facilitating swift decision-making. Achieving process linkage and data integration marks the culmination of visualization, significantly elevating production management in Thailand.

Successful Improvement Case in Thailand

A Japanese automotive parts manufacturer in Thailand improved production management efficiency by digitizing on-site forms. Previously, production quantities and defect information were handwritten on paper and later re-entered into Excel, resulting in redundant work and frequent errors, delaying information sharing.

By introducing the electronic form system “i-Reporter,” which allows the use of existing paper form layouts on tablets, they eliminated redundant work and significantly reduced input errors. Data entered on-site is aggregated in real-time to the cloud, enabling managers and the Japanese headquarters to instantly grasp the situation, eliminating reporting time lags.

The acceleration of information transmission and improved data accuracy greatly enhanced on-site responsiveness, leading to reduced delays and waste.

How TOMAS TECH Can Support Production Management in Thailand

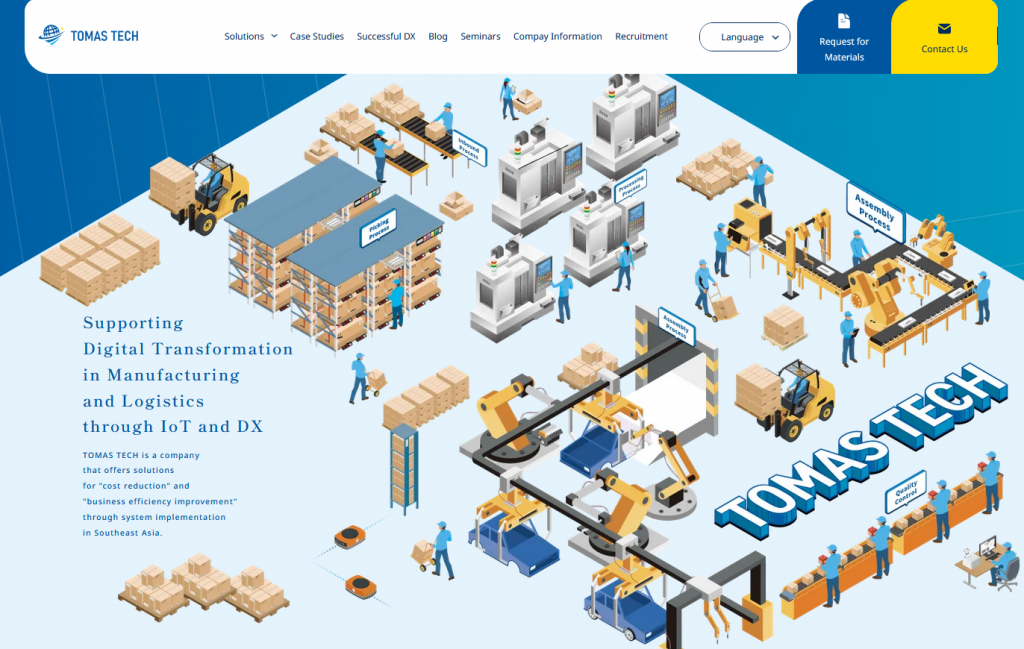

Improving production management in Thailand can benefit from the support of professionals familiar with local conditions. TOMAS TECH, based in Thailand, assists manufacturing companies in DX for production and inventory management, offering comprehensive support tailored to Japanese companies’ challenges.

Here are key support areas include:

- Organizing Local and Gathering Requirements: Multilingual staff conduct on-site interviews to identify and clarify local business requirements and challenges.

- Phased Implementation Support: Develop and execute a step-by-step implementation plan, providing thorough support at each stage to ensure on-site adoption.

- System Integration Across Processes: Link production management systems with inventory and logistics systems to create an environment for real-time information sharing company-wide.

TOMAS TECH’s strength is in providing these services seamlessly. With multilingual training for local staff and a robust post-implementation support system, even companies introducing systems in Thailand for the first time can proceed with confidence.

If you’re considering improving production management with the help of a knowledgeable local partner, consulting with TOMAS TECH might be a valuable step. Experts can help organize challenges and propose plans suited to your situation.

Frequently Asked Questions About Production Management in Thailand

Here are answers to some frequently asked questions about production management in Thailand.

Q: I’m concerned about implementing a system all at once. Can we proceed step by step?

A: Yes, it’s possible. Starting with small changes, such as eliminating paper and Excel or introducing input terminals on-site, is recommended. This approach prevents confusion on-site while gradually progressing.

Q: Is it possible to operate with only Thai staff?

Yes, A multilingual user interface and well-prepared operation manuals designed for on-site use are essential. At TOMAS TECH, we offer bilingual support in both Japanese and Thai, and we can also provide education and training assistance.

Q: How much does a production management system cost?

A: Costs vary depending on the scale of the factory and the scope of implementation. There are a wide range of options, from low-cost subscription-based tools to fully customized systems tailored to your company. We recommend starting with our “hearing + preliminary diagnosis” to propose a plan based on your budget and challenges.

Summary: “Step-by-step visualization” is the key to production management in Thailand

This article has outlined common issues in Thai production sites and how to improve them. Challenges such as “production delays,” “paper-based inefficiency,” and “person-dependent training” can be addressed with the right steps. The key is to gradually visualize operations on the ground.

Rather than aiming for perfection all at once, collect data step by step, make operations visible, identify issues, and implement solutions accordingly—this is how steady improvement can be achieved. Production management in Thailand will not proceed in the same way as in Japan, but by taking the right approach suited to local conditions, a path forward can be found.

If you feel your company has reached its limits in dealing with these issues alone, consider seeking help from local professionals. Partnering with experts will significantly increase both the speed and reliability of your solutions. Why not consult with a production management improvement specialist and take your next step forward?