i-Reporter is the best DX tool in Japan

![]() 16-Oct-2022

16-Oct-2022 ![]() 16-Oct-2022

16-Oct-2022

Conclusion

By using i-Reporter,

・You can streamline the time involved in creating forms

・Zero errors in form entry/transcription

・Costs related to paper, printing, and management can be reduced

・Because it can support multiple languages, reporting and consultation will be smooth.

・Customers can create reports without code

Isn’t there a growing trend toward digitization and DX at manufacturing sites? However, many of our customers may be worried, “I don’t know where to start” or “I don’t know what to do.”

This time, it is recommended for expatriates who are active overseas. We will propose a DX plan that is easy to make and the strongest cost performance.

It is a proposal to switch the paper forms used in the field to tablets and digitize them.

In addition to reducing paper costs, printing costs, and administrative costs, there are various benefits such as shortening work time by recording on paper, preventing valuable and transcription errors, and facilitating communication.

We will explain the problems and effects before introduction in an easy-to-understand manner.

Table of contents ∇

1 What’s i-Reporter?

2 Issues at manufacturing sites

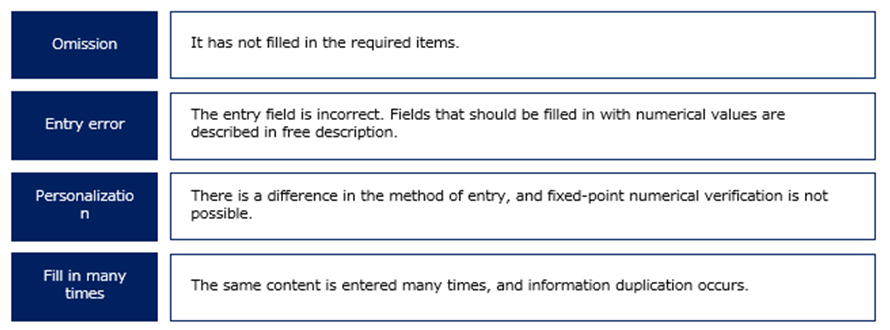

2.1 Problems when filling out forms

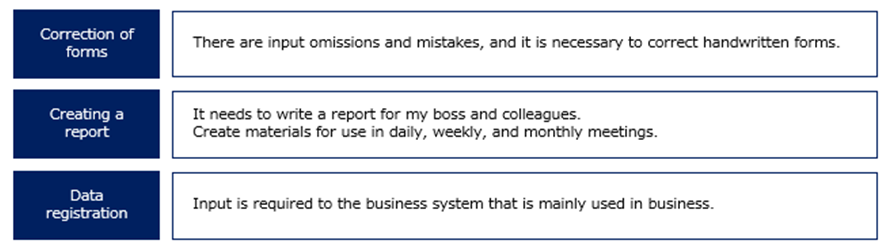

2.2 Enormous man-hours for post-processing

3 What we can do with i-Reporter

3.1 Four features of i-Reporter

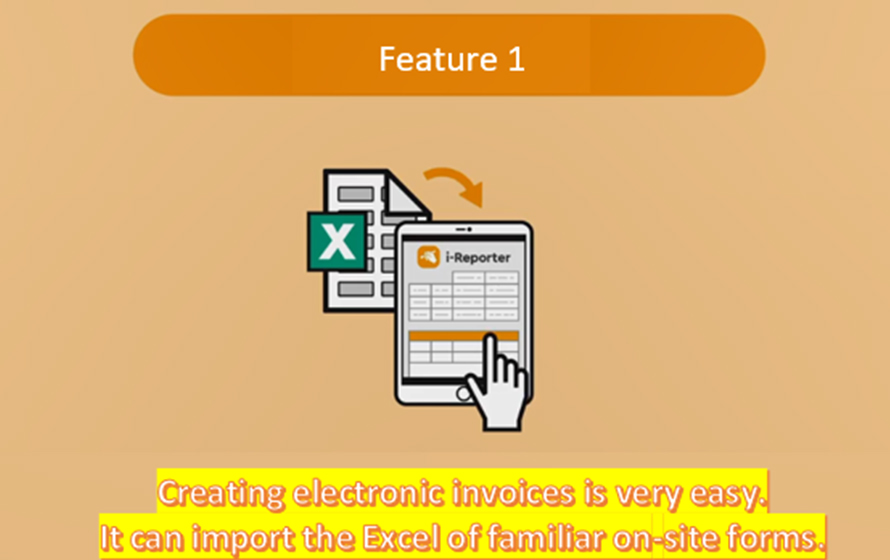

3.1.1 Feature① Very easy form creation

3.1.2 Feature② Can be used even in an offline environment

3.1.3 Feature③ Centralized management of form data

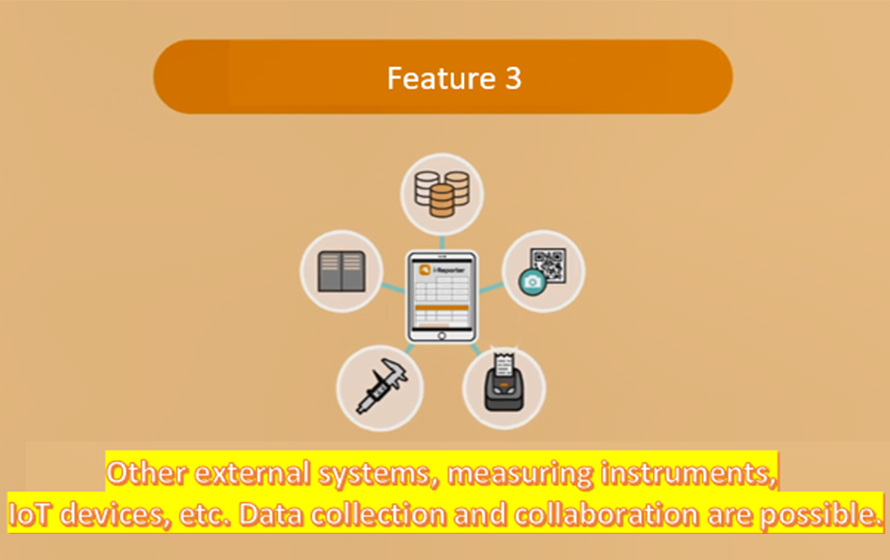

3.1.4 Feature④ Linkage with external systems and measuring instruments is possible

3.2 10 representative functions of i-Reporter

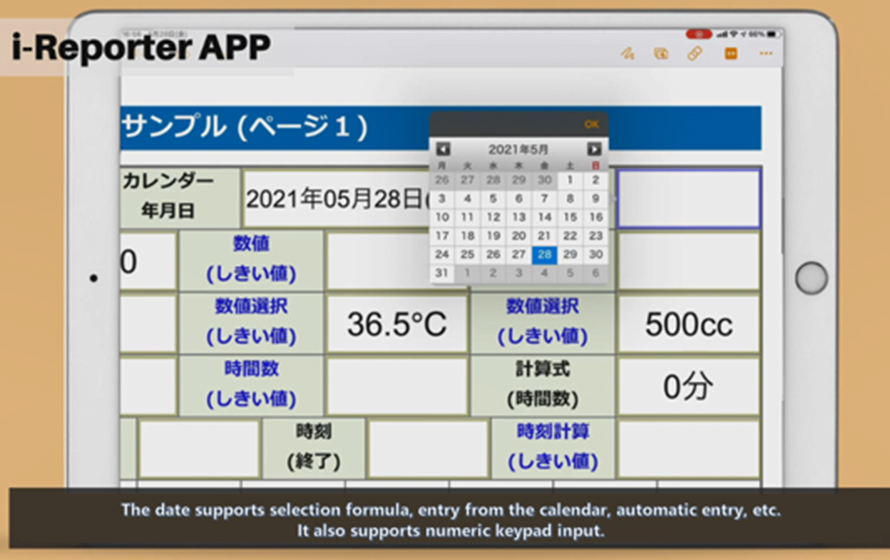

3.2.1 Function① Various data input formats

3.2.2 Function② Data entry error checking

3.2.3 Function③ Change cell color

3.2.4 Function④ List selection formula input

3.2.5 Function⑤ Automatic time calculation

3.2.6 Function⑥ Various check inputs

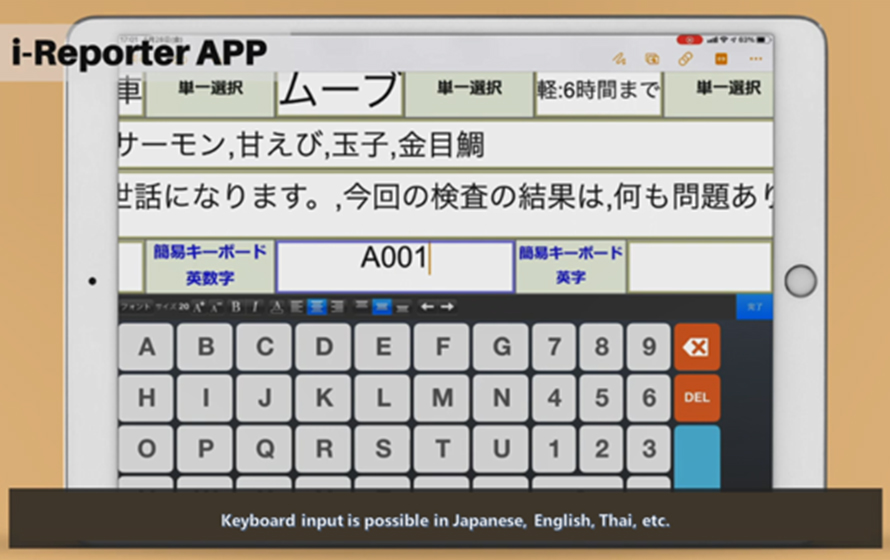

3.2.7 Function⑦ Easy keyboard input

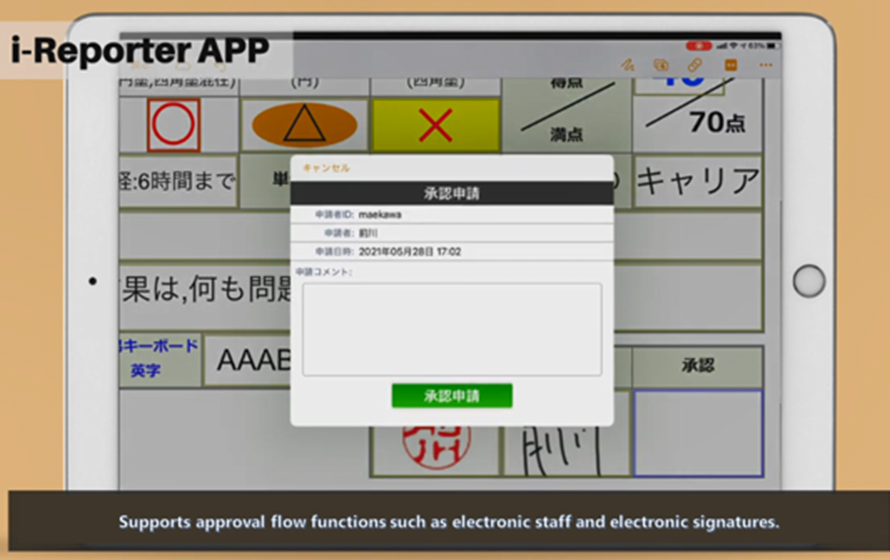

3.2.8Function⑧ Approval request flow

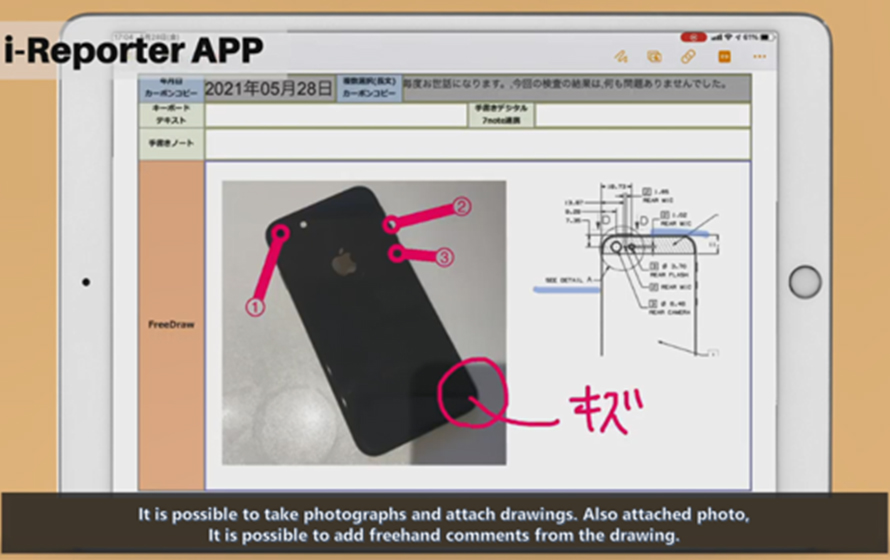

3.2.9Function⑨ Photo shoot/freehand

3.2.10 Function⑩ Barcode/QR code scanning

4 Summary: Utilization of i-Reporter at Manufacturing Sites

i-Reporter is a tool that can digitize and paperless various on-site reports in all industries, and has been introduced by more than 3,000 companies! It is the No.1 share application among paperless apps.

Familiar paper and Excel forms can be turned into electronic forms on the Tablet as they are.

It can digitize and go paperless while keeping the goodness of handwritten paper forms.We will digitize the paper work that we could not get out of until now, and complete the recording and reporting work on site.

At manufacturing sites where recording on forms is essential, there are many paper-related issues. Enter paper forms on site and collect them at the office. Isn’t there a lot of post-processing man-hours in the office?We observe the following four issues with the use of paper forms.

Creating electronic invoices is very easy. It can import the Excel of familiar on-site forms.

Since i-Reporter is a native application, it can be used even in an offline environment.

It is possible to centrally manage the form data in one database.

Data can be collected and linked with other external systems, measuring instruments, IoT devices, etc.

The date supports selection formula, entry from the calendar, automatic entry, etc.It also supports numeric keypad input.

It is possible to control the input of unexpected numerical values and data.

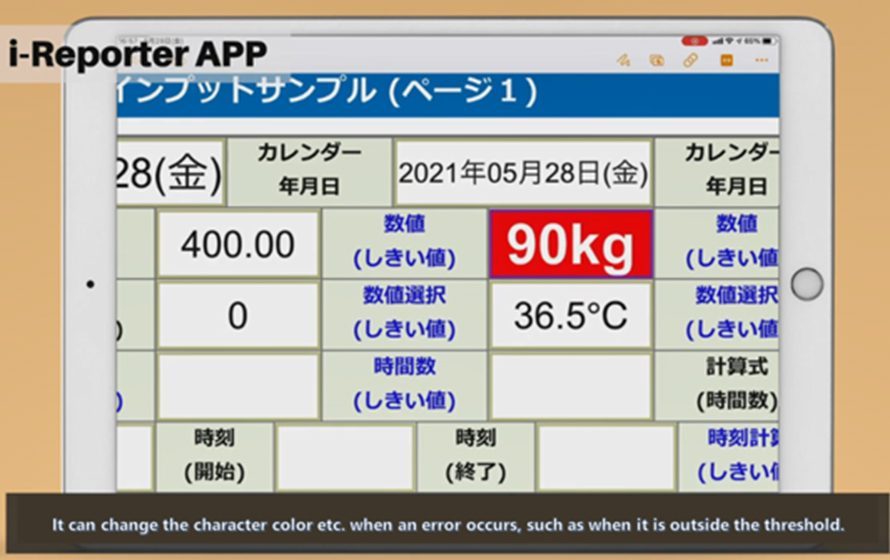

It can change the text color, etc. when an error occurs, such as when the threshold value is incorrect.

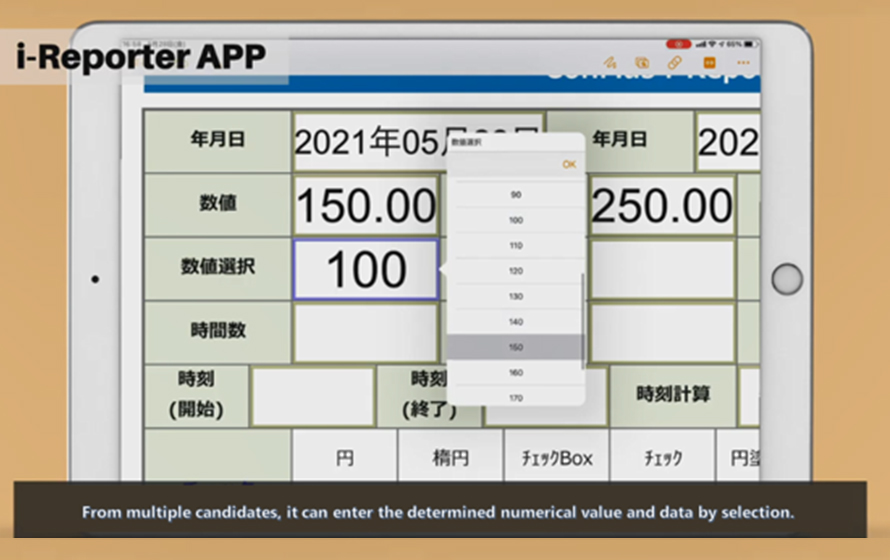

From multiple candidates, it can enter the determined numerical value and data by selection.

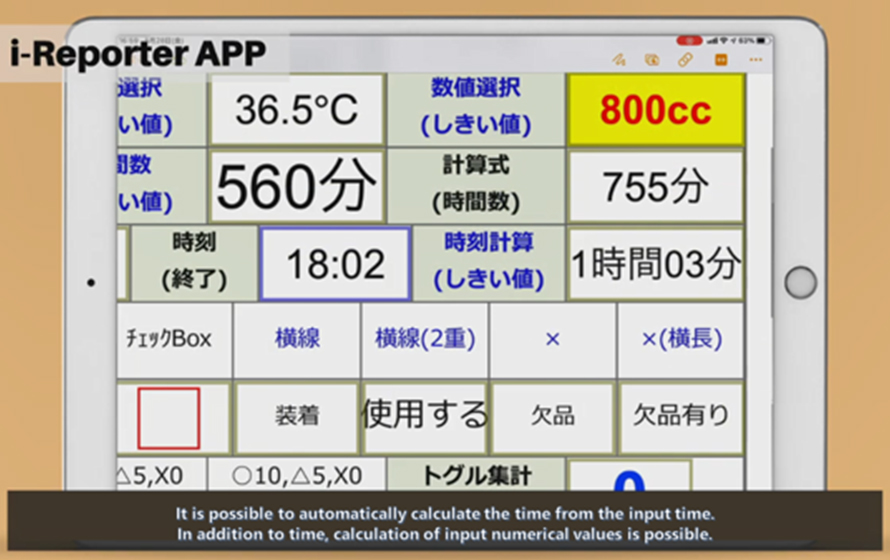

It is possible to automatically calculate the time from the input time. In addition to time, calculation of input numerical values is possible.

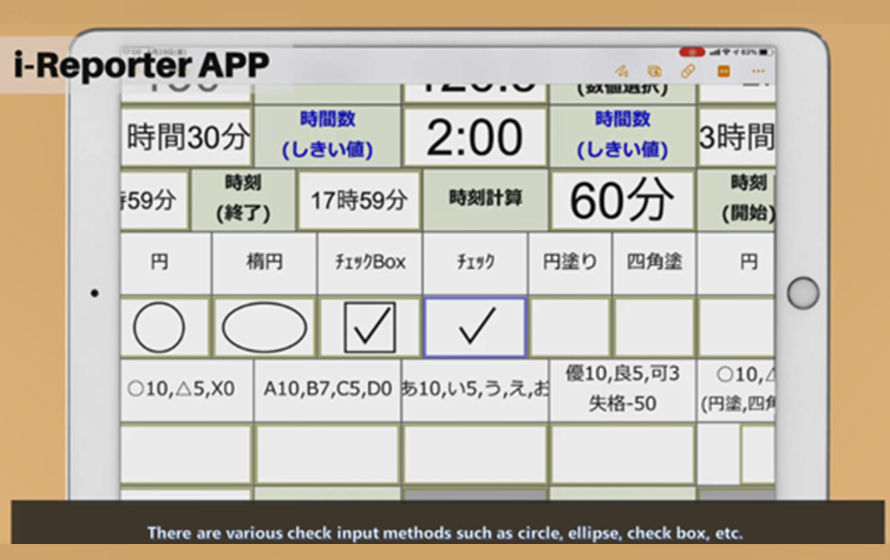

There are various check input methods such as circle, ellipse, check box, etc.

Supports approval flow functions such as electronic staff and electronic signatures.

It is possible to take photographs and attach drawings. You can also add freehand comments from the attached photos and drawings.

Barcodes and QR codes can be scanned, reducing the time and effort required to enter information.